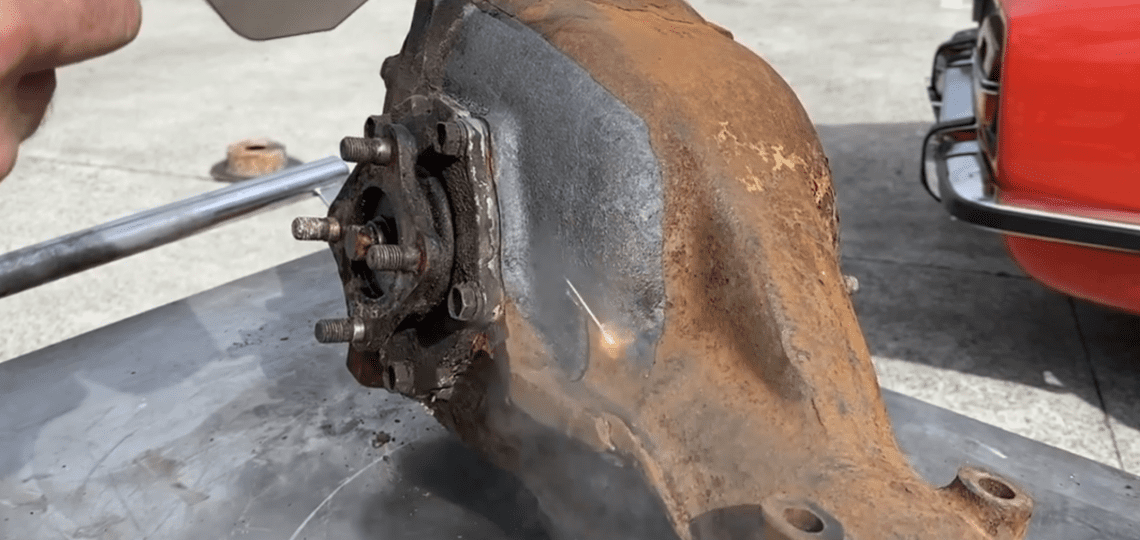

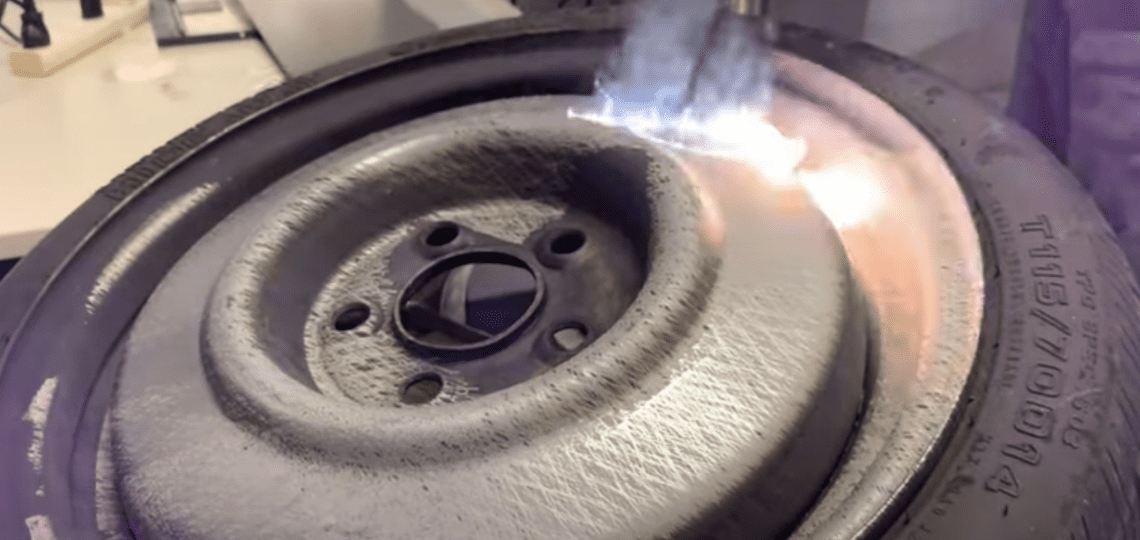

This laser cleaning machine uses an efficient, green cleaning technology. Compared with the chemical cleaning method, it does not require any chemicals and cleaning fluids. And it has many features, such as no grinding, no stress, and no consumables. Therefore, it is popular in various industries. This machine is cleaned by laser and has features – no grinding and non-contact. The laser cleaning machine is suitable to clean not only organic pollutants, but also inorganic substances, including metal rust, metal particles, dust, etc. It can achieve the processing effects of rust removal, paint removal, oil removal, cultural relic repair, glue removal, coating removal, and plating removal. Moreover, It is suitable for cleaning processes, such as rust, thin paint layer, shallow oil stain or technical, derusting of metal polished surface, pre-heating process treatment of sheet metal parts, and other processes.

Laser cleaning machine is an automatic equipment that releases a high-energy pulsed laser beam to irradiate and remove the rust, dust, contaminant, painting, and oxide on the surface of the workpiece. The principle of laser cleaning technology is that the contaminants on the surface of the workpiece melt or evaporate instantly after being irradiated by the pulsed laser beam so that the surface of the workpiece becomes clean. Laser cleaning is efficient and eco-friendly. It is becoming more and more popular in various industries.

The efficient laser cleaning lies in the fiber laser generator which releases high-density fiber laser beams. Traditional industrial cleaning methods usually use chemical reagents or mechanical methods to remove the contaminants on the surface of the workpiece. These methods have some disadvantages, such as low efficiency, damage the substrate or generate additional contaminants. Moreover, with the increasingly strict environmental protection laws, there are fewer chemicals that can be used in industrial cleaning. Therefore, looking for an eco-friendly cleaning method is a major problem for many companies.

The table below is a comparison of various cleaning methods. Compared with the traditional mechanical cleaning method, chemical cleaning method and ultrasonic cleaning method, laser cleaning does not require any organic solvents and is pollution-free. The laser cleaning process has no noise and no damage to the human body and environment.

Cleaning Methods | Laser Cleaning | Ultrasonic Cleaning | Dry Ice Cleaning | Chemical Cleaning | Mechanical Grinding |

Cleaning medium | Laser | Cleaning agent | Dry ice | Chemical cleaning agent | Mechanical/abrasive paper |

Contact cleaning or non-contact cleaning | Non-contact | Contact | Non-contact | Contact | Contact |

Workpiece damage | No damage | No damage | No damage | Damage | Damage |

Cleaning efficiency | High | Middle | Middle | Low | Low |

Consumable | Only electricity | Cleaning agent | Dry ice | Chemical cleaning agent | Abrasive paper, grinding wheel, whetstone, etc. |

Cleaning effect | Excellent, high cleanliness | Good, small clean area | Good, uneven | Medium, uneven | Medium, uneven |

Cleaning precision | Precise and controllable, high precision | Cannot specify cleaning range | Uncontrollable, low accuracy | Uncontrollable, low accuracy | Uncontrollable, medium accuracy |

Safety and environmental protection | No chemical pollution | No chemical pollution | No chemical pollution | Chemical pollution | Rust/debris pollution |

Manual operation | Simple operation, handheld or automated | Simple operation, need to manually add consumables | Simple operation, handheld or automated | Complicated processing flow, high requirement on operator, require pollution prevention measures | High manpower consumption, require pollution prevention measures |

Cost | High initial investment, no consumables, low maintenance cost | Low initial investment, medium consumables cost | Medium initial investment, high consumables cost | Low initial investment, high consumables cost | High initial investment, high consumables cost, high labor cost |

The invention of laser cleaning technology opens a door for enterprises and individuals by virtue of its non-contact processing, environmental protection, low processing cost and low thermal effect. Laser cleaning machine is the best solution for industrial cleaning.

Laser cleaning machine uses laser ablation principle to remove the dust on the metal surface. Laser ablation is a type of physical reaction. When the high-density laser beam irradiates on the metal surface, it is absorbed by the pollution layer on the metal surface. The absorption of large energy forms a rapidly expanding plasma which generates shock waves, and the shock waves turn the pollutants into fragments and remove them off the metal surface. The laser ablation reaction occurs in this way and makes the rust, dirt and oxide layer melt and evaporate very quickly.

Different materials have different properties, so each material has a specific ablation threshold. As long as the energy of laser beam is above the ablation threshold of the dust that needs to be removed, the laser beam can successfully remove the dust. The ablation threshold of rust, oil or painting is much lower than metals like stainless steel, carbon steel, aluminum, etc. Therefore, if the laser parameters are set reasonably, the laser cleaning process will not damage the substrate and leave a very clean surface.

As the laser cleaning machine uses laser ablation to remove dust, there is no consumables required during the laser cleaning process. The traditional industrial cleaning methods like chemical cleaning, ultrasonic cleaning or dry ice cleaning need cleaning reagent to finish the cleaning process, which improves the processing cost and labor cost. Laser cleaning method solves the problem perfectly and it is pollution-free. More and more enterprises prefer use the laser cleaning machine to clean metal parts and restore equipment surface.

Acco

Compared with the traditional industrial cleaning methods, laser cleaning machine has the following advantages:

rdion Content

Laser cleaning machine has the characteristics of non-contact, no thermal effect, no mechanical force on metal surface, no consumables and low processing cost. This machine has been widely used in many industries. So how to use a laser cleaning machine after you buy one? Here are the main steps for your reference. Please always remember that you need to read the operation brochure provided by the manufacturer to understand the precautions and operation instructions. Wear protective glasses and other protective equipment to ensure your safety. And do not look directly at the laser output position with you eyes during the cleaning.

During the operation of a laser cleaning machine, the processing materials usually generate a large amount of corrosive dust and smoke. These dust and smoke are deposited on the surface of the guide rail and linear shaft for a long time. If we don’t clean them timely, they will affect the machine’s cleaning accuracy. What’s more, these dust and smoke will form corrosion points on the surface of the guide rail and shorten the machine’s service life. Therefore, to keep the laser cleaning machine work normally, stably and ensure the cleaning quality, we need to maintain the machine timely and regularly. We can follow below tips to maintain the laser cleaning machine.

n Content

More and more companies and individuals want to buy a laser cleaning machine to support their business. How to buy a suitable laser cleaning machine that fits your needs? You can follow the below three steps.

Our main products are industrial metal laser cutting machines. Besides, we can provide users with fiber laser cutters, co2 laser engraving machines, laser marking machines as well as CNC routers.

© Copyright 2023 GBLCNC All rights reserved